Intel Boasts of Progress With PowerVia Technology

Intel has announced that it has made significant progress with its proprietary PowerVia technology, and is the first chipmaker to create a production-worthy test chip with backside power delivery, putting it two years ahead of the competition.

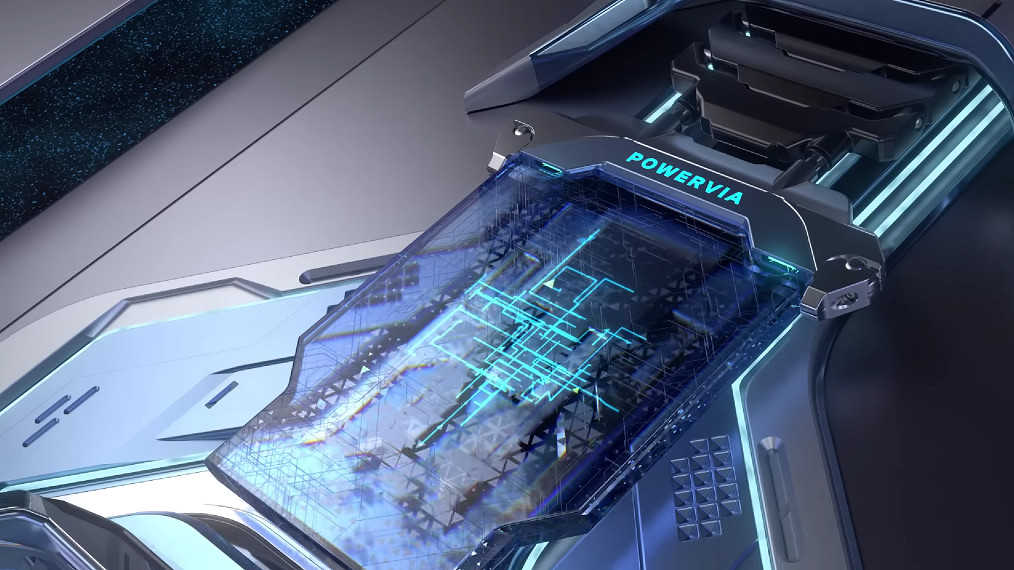

Blue Sky Creek Chip

The Blue Sky Creek chip contains 8 E-cores and runs at 3 GHz. The unique thing about this processor is that it no longer has the traditional structure of current CPUs. This is based on a structure that runs from small to large when viewed from the bottom: transistors at the bottom, interconnects above.

From nanometer to Ångström

Those who follow the development of processor technology know that we have seen increasingly smaller processes in recent decades. Chip manufacturers are constantly competing to get more power on a smaller piece of silicon. In this battle, Intel seemed to fall behind, sticking to the 14 nanometer naming convention. This while AMD let Ryzen chips bake on 7 and 5 nanometer TSMC processes, for example. However, this is rather a situation where we are talking about other technologies. Just as clock frequency and number of cores don’t necessarily tell the whole story, these processes aren’t directly comparable.

Intel now states that it has actually taken the lead in the battle for smaller processes, following the “five nodes in four years” ambition that Intel CEO Pat Gelsinger expressed in 2021. PowerVia tech is located at 20 Ångström, or 2 nanometers. According to VP of technology at Intel Ben Sell, the breakthrough is an important milestone. The pilot chip puts Intel “a process ahead of our competition in bringing backside power delivery to market.” PowerVia is said to be the power behind the Arrow Lake generation of Intel, which is planned in the first half of 2024.

Advantages

Specifically, the test chip should bring about quite a few improvements through the architectural change. For example, there would be more space for the interconnect layer due to the disappearance of the power supply at the front. There would be 30 percent less voltage droop and a 6 percent frequency advantage. Purely in terms of appearance, little changes and there should not even be a problem with heat build-up, despite this build-up being completely new to production chips.

Intel has made a major breakthrough in the chip industry with its PowerVia technology. The Blue Sky Creek chip is the first production-worthy test chip with backside power delivery, putting Intel two years ahead of the competition.

The chip contains 8 E-cores and runs at 3 GHz, and has a structure that runs from small to large when viewed from the bottom. This structure creates bottlenecks in terms of interconnect speeds and the stability of the power supply, but this should be a thing of the past with backside power delivery.

Intel has taken the lead in the battle for smaller processes, following the “five nodes in four years” ambition that Intel CEO Pat Gelsinger expressed in 2021. PowerVia tech is located at 20 Ångström, or 2 nanometers. This breakthrough is an important milestone, and the pilot chip puts Intel “a process ahead of our competition in bringing backside power delivery to market.”

The test chip should bring about quite a few improvements through the architectural change. There would be more space for the interconnect layer due to the disappearance of the power supply at the front. There would be 30 percent less voltage droop and a 6 percent frequency advantage. Purely in terms of appearance, little changes and there should not even be a problem with heat build-up, despite this build-up being completely new to production chips.

Intel’s PowerVia technology is an important milestone in the chip industry, and the Blue Sky Creek chip is the first production-worthy test chip with backside power delivery. This puts Intel two years ahead of the competition and should bring about a number of improvements in terms of interconnect speeds, power supply stability, voltage droop, and frequency advantage.